Environment

Climate mitigation

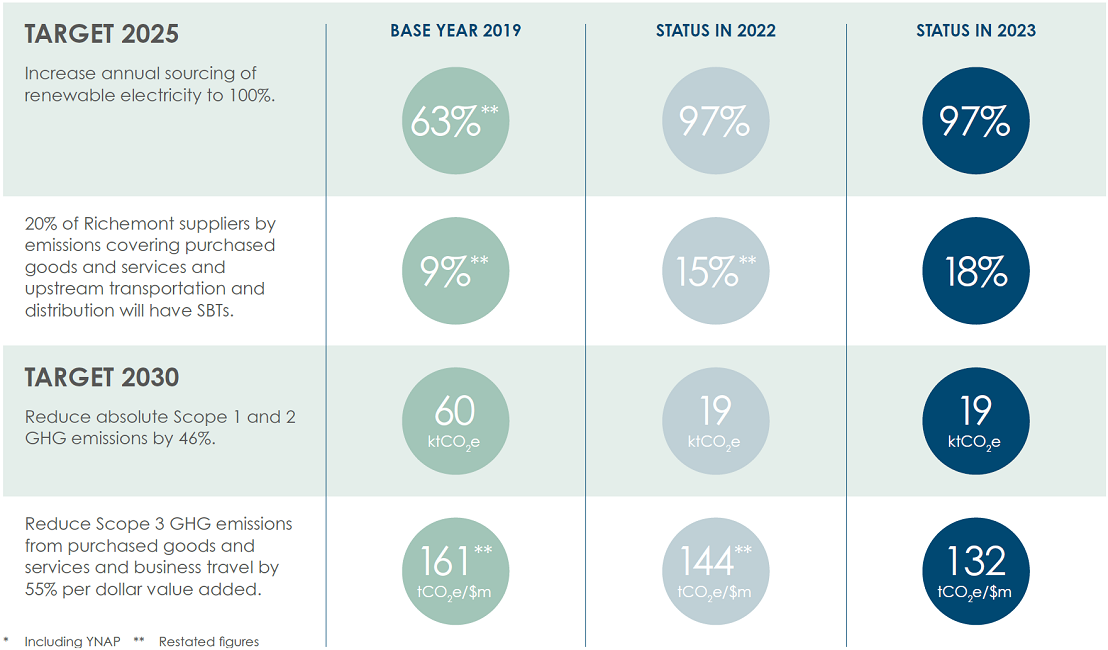

The Group mitigates its impact on climate by reducing emissions from its direct operations and supply chains.

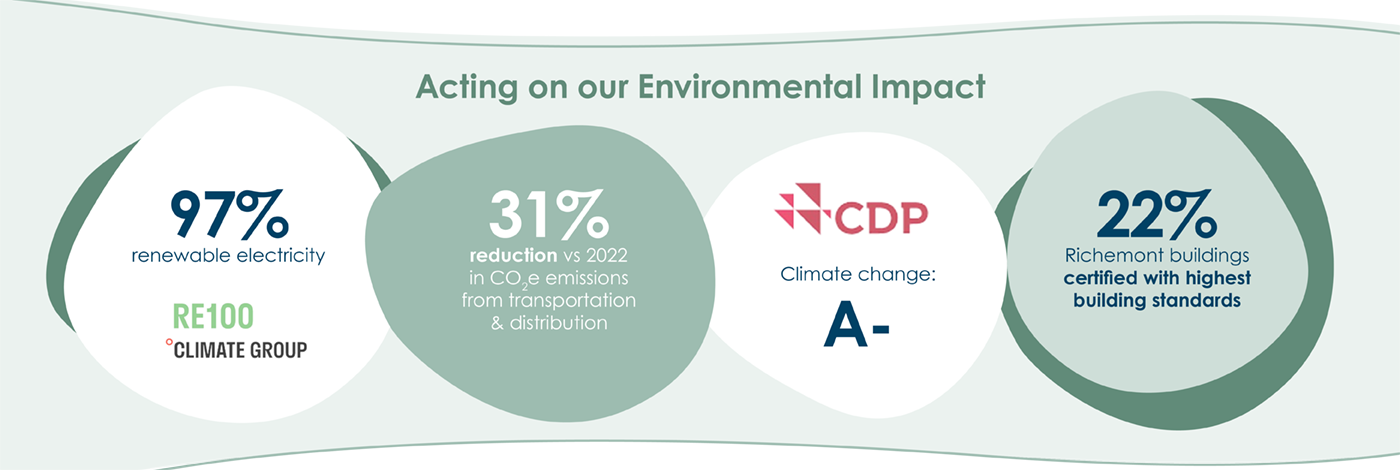

Richemont has been tracking its Scope 1, Scope 2, Scope 3.4 (upstream transportation and distribution), and 3.6 (business travel) emissions for over a decade. In 2023, upstream transportation and distribution declined by 31% compared to 2022, mainly due to the shift from air freight to shipping by sea and lower volumes observed in certain product categories.

Biodiversity conservation

Richemont is developing its understanding of ecosystem impacts and dependencies it has on ecosystem services provided by nature. The Group complies with international and local regulations and aligns with the Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES).

Richemont conducted an initial biodiversity screening to determine the Group’s biodiversity impact and identify high priority risks and opportunities across its supply chains. Based on the results of the biodiversity screening, in June 2023, Richemont conducted a footprint analysis to estimate the land-use of the Group’s supply chain.

Freshwater stewardship

The Group has been monitoring its water withdrawal for several years. Specifically, the Group has conducted a study using three different measures (water stress, water depletion, and blue water scarcity) with open data sources, such as the WRI Aqueduct, to identify the number and type of owned buildings located in water stressed areas.

In 2023, water withdrawals increased by 30% in absolute quantities compared to 2022. This increase concerns all sources of water used at Richemont. Only 2% of Richemont’s water withdrawals occur in buildings located in ‘high’ or ‘extremely high’ level of baseline water stress (>40% baseline water stress).

Working to address environmental challenges

|

Pollution prevention and control |

Richemont recognises that the responsible management of emissions and discharges is an important element of sustainable environmental practices. The Group has dedicated teams for the responsible management of hazardous chemicals, namely Health, Safety and Environment (Group HSE) and the Chemical Competence Center (CCC). In 2023, the Group started to collect data on Non-Methane Volatile Organic Compound (NMVOC) emissions associated with the use of various fossil fuels and solvents. Wherever the Group has more intensive operations, it has installed local wastewater treatment plants to mitigate potential negative impacts. For tanneries, the Group requires suppliers to have Leather Working Group (LWG) certification. |

|

Responsible resource use |

The Group acknowledges that resources need to be used in a responsible manner in its activities. Richemont’s Environmental Code of Conduct outlines the commitment to monitoring resource consumption and managing resource-related risks. The SCoC also emphasises the need for suppliers to continuously minimise their resource consumption. Richemont has identified a list of critical raw materials, itself a subset of the EU and US lists of critical materials. These materials include copper, nickel, palladium, platinum group metals, titanium metal, tungsten and zinc. The Group has implemented measures to reduce risks associated with these materials, such as keeping them in circulation longer while implementing responsible sourcing practices. |

|

Buildings efficiency |

Richemont has an extensive real estate portfolio covering approximately 1.2 million square metres, with around 1 500 buildings globally. It is a priority for the Group to ensure these buildings operate efficiently. To date, 22% of the buildings owned by the Group are certified in accordance with international, national or local standards, such as LEED New Construction, LEED Operations and Maintenance, BREEAM, Minergie, SNBS, Fondation Nature & Economie and SméO. |

|

Energy management |

Richemont manages energy consumption in its activities while considering the prioritisation of renewable energy and energy efficiency gains. It is a member of the RE100 and has formally committed to sourcing 100% renewable electricity by 2025. In 2023, 97% of Richemont’s electricity consumption came from renewable sources. This included 63% purchased from retail supply contract mainly providing hydropower, 33% unbundled procurement of energy attribute certificates (EACs) and 1% self-generated production such as on-site solar facilities. |

|

Circularity |

The Group’s commitment to circularity extends beyond the durability of products to include design, materials, packaging, servicing and repair. The environmental impact of Richemont products is evaluated through multi-criteria Product Lifecycle Assessments (LCA) following the ISO 14040/14044 standards and the Product Environmental Footprint (PEF) recommendations from the European Commission. The Group’s product design teams rely on these evaluations to identify hotspots and explore alternative solutions. The Group’s Research & Innovation team has created the Circle Material platform that helps put unused stock to use by sharing the different types of leather and textile that are in stock but not used by a Maison and thus available to others for prototyping, gift developments or other usage. |

|

Waste management |

Richemont aims to minimise waste in its own operations. In 2023, Richemont reported 17 250 tonnes of waste, a 24% increase compared to the previous year, mainly due to improved data accuracy, categorisation and reporting scope. Examples of initiatives to reduce and manage waste undertaken by Maisons include the work of the Campus Genevois de Haute Horlogerie in Meyrin in conjunction the Services Industriels de Genève (SIG) to assess its recycling channels. This contributed to an estimated overall recycling rate of 66% for 2023. |